Damper

Gas spring use oil as damper to buffer. The Following are the descriptions of commonly used dampers:

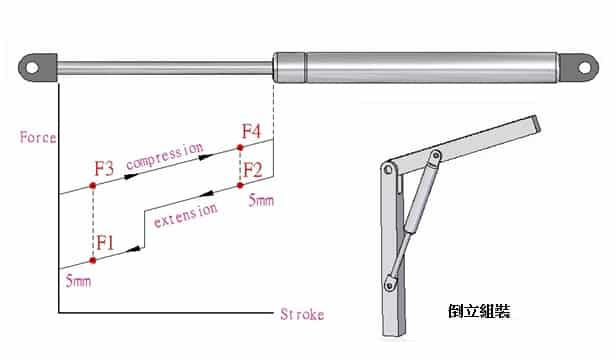

The graph indicates when you pressed it to F4 position, it generates greater damper force.The product is upright assembled, which means that gas springs are assembled upward.The range of applications: the damper is generated when the workpiece needs to be dropped down without making a large noise, such as treadmill, door, or damping buffer slide…etc.

The graph indicates that the damper generated when you raise it to the F1 position.The product is assembled upside down, which means that gas springs are downward assembled.The range of applications: the damper is generated when the workpiece needs to be rose to the highest point with a smooth movement, such as cabinet, copier flip, car hood, car boot, and furniture parts…etc.

The choice of Gas spring

There are total of four positions, F1, F2, F3, and F4 that define the force values of a gas spring,this may also be referred to as the extension force ofthe gas spring.

F3 and F4 are the compression of a gas spring.

F2 and F1 are the extension of a gas spring.

Point F1 is 5mm force value before a gas spring extends up to the highest point.

The F1’s force value decides whether or not the nitrohen inside a gas spring has sufficient force to support the workpiece to the desirable location.

The informations is based on the exter of gas spring

A. Fitting: different fittings can be chosen according to the product.

B. Piston rod: this part is to control the actual movement distance of product, so-called “Stroke”.

C. Steel tube: injecting different forces of nitrogen within according to different needs, so-called “gas cell “

B. Piston rod: this part is to control the actual movement distance of product, so-called “Stroke”.

C. Steel tube: injecting different forces of nitrogen within according to different needs, so-called “gas cell “

Calculation of Gas Spring Force Values

F1=(W x d1) / (N x d2)

ö:Center of gravity(door’s center point)

W (pound): Door weight

d1(meter): Horizontal distance between the fulcrum and gravity center

d2(meter):Horizontal distance between the fulcrum andgas spring

N:The number of gas spring (the common design is for 2)

F1: The force of gas spring’s stretching direction

ö:Center of gravity(door’s center point)

W (pound): Door weight

d1(meter): Horizontal distance between the fulcrum and gravity center

d2(meter):Horizontal distance between the fulcrum andgas spring

N:The number of gas spring (the common design is for 2)

F1: The force of gas spring’s stretching direction

Instructions

1. Gas spring are filled with pure nitrogen,which is an inert gas that does not

burn, will not explode and is not poisonous.

2. Gas springs have very high internal pressure. Do not open it without instruction!

3. The regular gas spring is installed inverted, which means that the piston rod is downward position. This way of installation method ensures the optimum damping effect. ( In a few cases, the gas springs need to be upright assembled.)

4. No tilted or displacement is allowed when assembling gas spring. If there is displacement after installation, you have to re-check assembly process whether an error occurred or to replace a more appropriate accessory connector.

5. There may be a stucking effect the first time you compress a spring, which may require a higher expenditure of force ( initial breakaway force )

6. The piston rod must not be painted and should be protected against shocks, scratches and dirt. The cylinder should not be deformed. Such damage will destroy the sealing system.

7. Gas spring is suitable in the temperature between+70℃〜 -20℃

8. The tolerance for the lengths is generally deemed to be ±2mm. Please avoid the combination of small diameter + long stroke + high force.

9. The Gas spring variation range is between +40N / -20N. Generally, the temperature will affect the force of gas spring ; every 10℃ changes, about 3.3% strong of gas spring’s force will change.

10. Every gas spring in our company is manufactured and tested with the highest standard.The team of Just Stretch commits itself to the best professional technology, providing you with the proper installation and use of gas spring, so that its function and life can be achieved to the best results.

It is our great pleasure to help you design the gas spring you need. Please feel free to contact us.

2. Gas springs have very high internal pressure. Do not open it without instruction!

3. The regular gas spring is installed inverted, which means that the piston rod is downward position. This way of installation method ensures the optimum damping effect. ( In a few cases, the gas springs need to be upright assembled.)

4. No tilted or displacement is allowed when assembling gas spring. If there is displacement after installation, you have to re-check assembly process whether an error occurred or to replace a more appropriate accessory connector.

5. There may be a stucking effect the first time you compress a spring, which may require a higher expenditure of force ( initial breakaway force )

6. The piston rod must not be painted and should be protected against shocks, scratches and dirt. The cylinder should not be deformed. Such damage will destroy the sealing system.

7. Gas spring is suitable in the temperature between+70℃〜 -20℃

8. The tolerance for the lengths is generally deemed to be ±2mm. Please avoid the combination of small diameter + long stroke + high force.

9. The Gas spring variation range is between +40N / -20N. Generally, the temperature will affect the force of gas spring ; every 10℃ changes, about 3.3% strong of gas spring’s force will change.

10. Every gas spring in our company is manufactured and tested with the highest standard.The team of Just Stretch commits itself to the best professional technology, providing you with the proper installation and use of gas spring, so that its function and life can be achieved to the best results.

It is our great pleasure to help you design the gas spring you need. Please feel free to contact us.